Powering Productivity with High-Performance Crushing Solutions

Material processing is the backbone of mining, aggregate, and construction operations. When your crushing system performs efficiently, everything downstream runs smoother, safer, and more profitably. That is why choosing the right equipment partner matters just as much as selecting the right machine.

From our base in Vernon, BC, we work with clients across Canada and around the world to deliver reliable, high-performance comminuting systems built for demanding environments. Through our partnership with OMRAISE, we provide advanced crushing and grinding solutions engineered for durability, precision, and output optimization. Whether you operate a large-scale mining site or a regional aggregate facility, our crushers are designed to help you move material with confidence and consistency.

Built for Demanding Canadian Conditions and Global Applications

Operating in Canada means dealing with diverse materials, remote sites, and challenging weather patterns. Crushing systems must be tough enough to withstand abrasive rock, heavy loads, and continuous production schedules. They must also deliver dependable performance without constant downtime.

We supply crushing equipment that is engineered for durability and efficiency. Every system we offer is designed with modern technology that enhances throughput while maintaining structural strength. Our clients rely on us not only for equipment supply but also for guidance, spare parts access, and technical support that keeps operations moving forward.

What sets our approach apart:

- Equipment engineered for high-capacity production

- Durable construction built for heavy-duty applications

- Efficient designs that reduce energy consumption

- Comprehensive support and parts availability

From Vernon to projects worldwide, we focus on providing crushing systems that stand up to real-world demands.

1.png)

@2x1-resized.png)

Our Crushers Engineered for Performance and Precision

Crushing is not a one-size-fits-all process. Different materials, capacities, and end-product specifications require specific equipment configurations. That is why we offer a range of crusher types designed to meet varied operational needs.

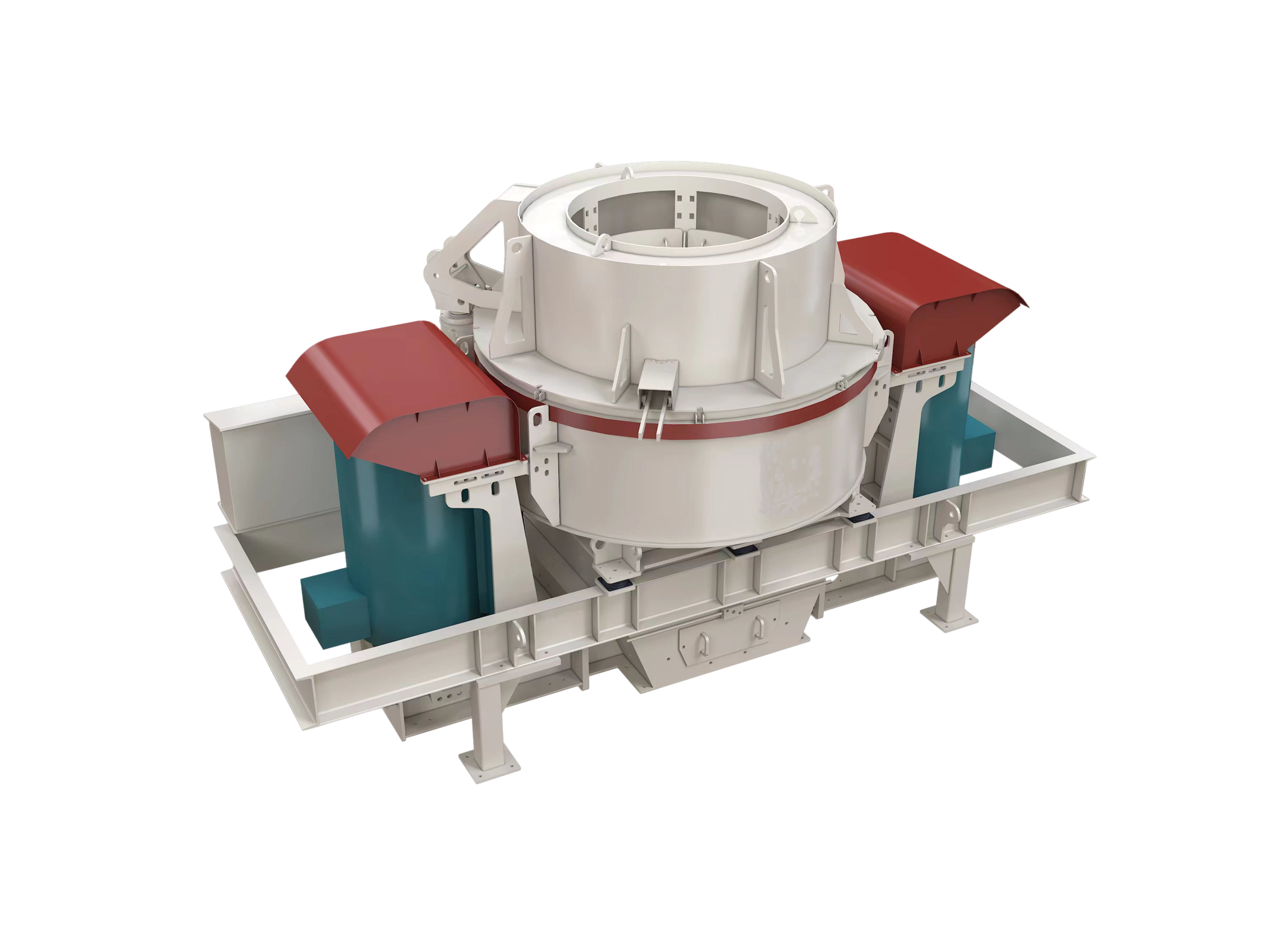

Gyratory Crushers High-Capacity Primary Power

Primary crushing sets the stage for the entire processing chain. Gyratory crushers are ideal for large-scale mining operations that require consistent, high-volume throughput. These machines are built for heavy-duty performance and can handle significant feed sizes while maintaining stable output.

Gyratory crushers are known for:

- High capacity processing

- Continuous crushing action

- Robust construction for demanding environments

- Efficient handling of hard and abrasive materials

For operations that demand reliable primary crushing with minimal interruption, gyratory systems provide a strong foundation.

Jaw Crushers Versatility You Can Count On

Jaw crushers are widely used across mining, aggregate, and construction industries because of their flexibility and reliability. These machines excel at breaking down various material types, making them an excellent choice for both primary and secondary crushing applications.

Key advantages of jaw crushers include:

- Adaptability to different feed materials

- Simple, durable mechanical design

- Efficient reduction ratios

- Easy maintenance access

Clients appreciate jaw crushers for their dependable performance and ability to manage a wide range of applications without compromising output quality.

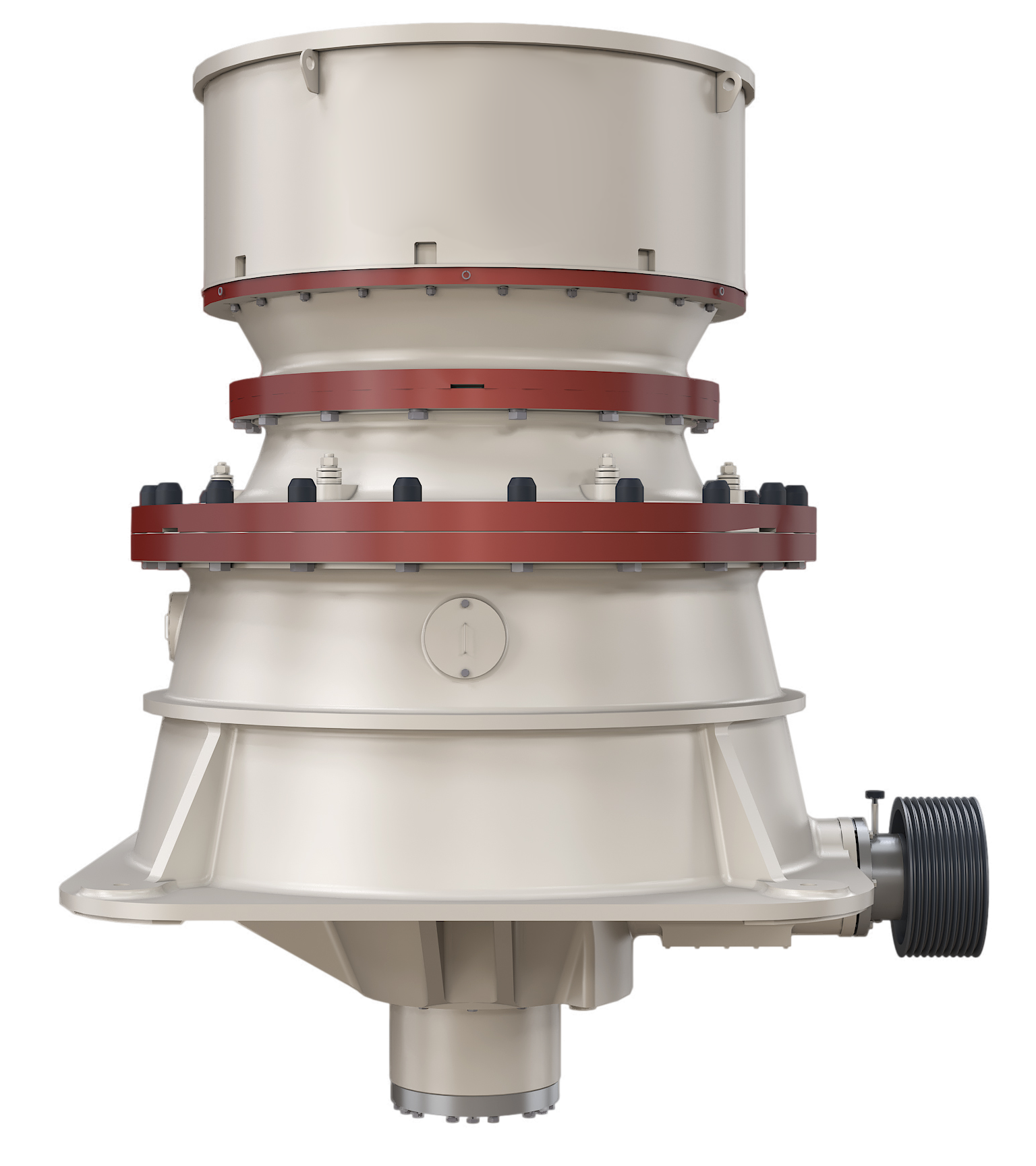

Cone Crushers Precision in Every Pass

When finer output and precise sizing are required, cone crushers deliver consistent and controlled performance. These machines are designed for secondary and tertiary crushing stages, refining material into the exact specifications needed for further processing or final use.

Cone crushers offer:

- Accurate particle size control

- High reduction efficiency

- Optimized chamber design for smooth material flow

- Strong structural integrity for extended operational life

Precision matters in material processing. Cone crushers help ensure that your final product meets project requirements without unnecessary reprocessing.

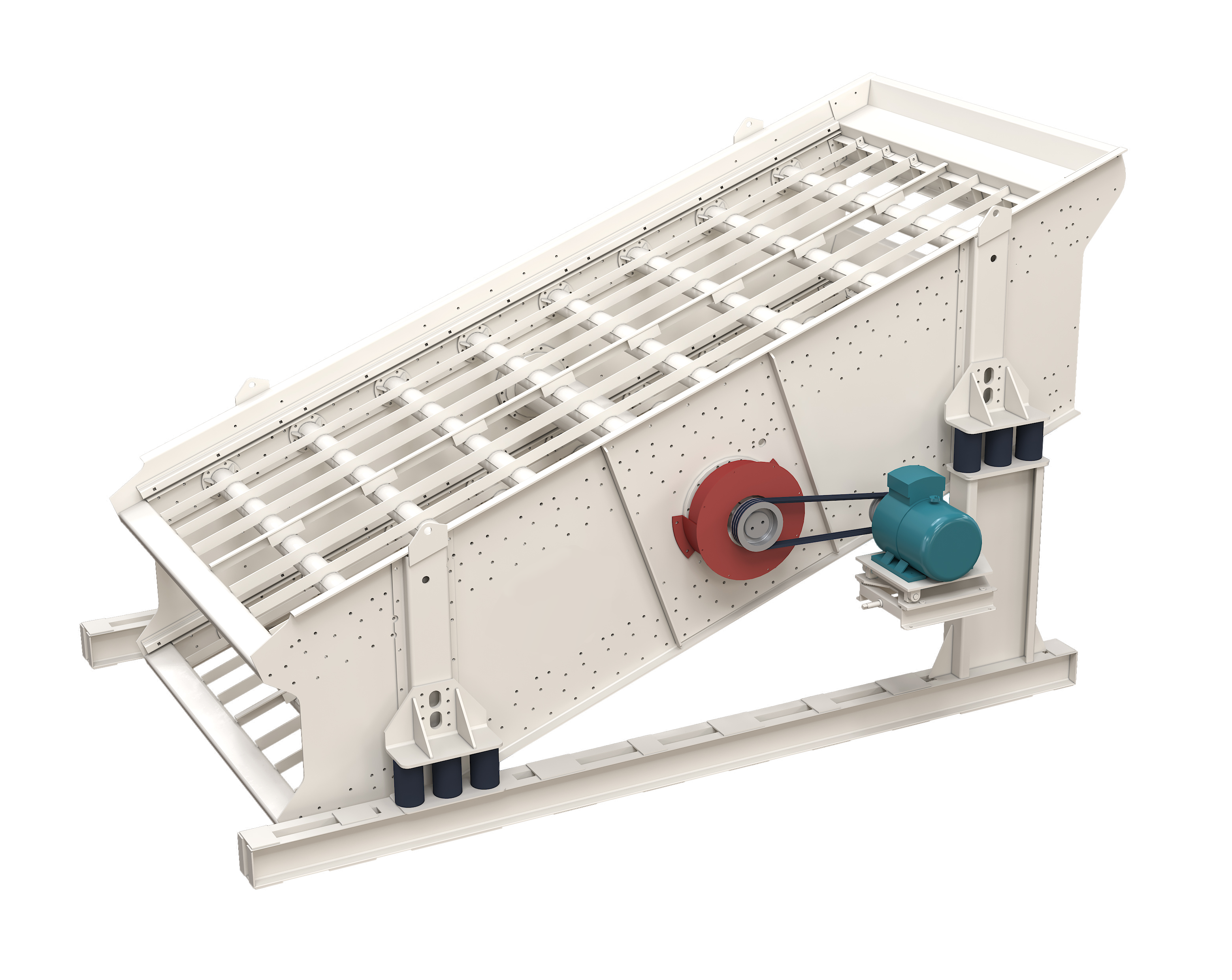

Impact Crushers High-Speed Efficiency for Aggregates and Recycling

Impact crushers use high-speed rotor systems to break material through forceful impact. They are particularly effective in aggregate production and recycling applications where speed and uniformity are essential.

Impact crushers provide:

- Fast material reduction

- Excellent shaping capability

- Versatility for different feed materials

- Effective performance in recycling operations

For operations focused on aggregate quality and production speed, impact systems deliver efficient and consistent results.

More Than Equipment A Commitment to Service and Support

Supplying high-performance crushers is only part of what we do. Our commitment extends beyond the initial sale. We understand that downtime can significantly affect productivity and profitability, especially in mining and aggregate industries where timelines matter.

We provide comprehensive support to ensure your crushing system continues to perform as expected. This includes spare parts availability, technical consultation, and expert guidance tailored to your specific application. Clients rely on us because we remain accessible and responsive long after equipment installation.

Our support philosophy centres on:

- Prompt spare parts access

- Knowledgeable technical consultation

- Clear communication throughout the process

- Practical solutions tailored to operational needs

When you work with us, you are not simply purchasing machinery. You are building a relationship with a team that understands material processing and stands behind the systems we supply.

Optimizing Productivity Through Smart System Design

Efficient crushing is about more than breaking rock. It involves understanding material characteristics, feed rates, and desired output sizes. A well-designed comminuting system reduces waste, improves consistency, and supports overall operational efficiency.

We work closely with clients to help identify the right crusher type and configuration for their specific project. By aligning equipment capabilities with operational goals, we help maximize output while maintaining equipment longevity.

A strategic approach to crushing can lead to:

- Improved material flow

- Reduced bottlenecks

- Enhanced product consistency

- Lower operational interruptions

Thoughtful equipment selection and planning contribute directly to smoother production cycles and stronger overall results.

Serving Vernon BC and Beyond

While we are located in Vernon, BC, our reach extends across Canada and internationally. Mining and aggregate operations operate in diverse environments, and our systems are built to adapt to these varying conditions. Whether you operate in British Columbia, elsewhere in Canada, or on a global project, we provide crushing solutions that align with your operational requirements.

Our focus remains on delivering reliable performance, practical expertise, and equipment designed to support demanding industrial applications. We understand the expectations of Canadian industries and the global market. Our goal is to help you achieve efficient, dependable material processing wherever your operation is located.

Frequently Asked Questions

Our crushers are primarily used in the mining, aggregate, and construction industries. These sectors require dependable material reduction systems to process raw materials into usable forms. From primary extraction to refined aggregate production, our equipment supports a wide range of material processing needs. Clients rely on our systems to manage heavy workloads while maintaining consistent output quality.

Selecting the right crusher depends on several factors, including the type of material, feed size, desired output size, and production capacity requirements. Gyratory crushers are typically suited for high-capacity primary applications, while jaw crushers provide versatile performance. Cone crushers are ideal for precise secondary or tertiary crushing, and impact crushers are often chosen for aggregate shaping and recycling. We work with clients to evaluate their specific needs and recommend the most suitable solution.

Yes, ongoing support is a core part of our service commitment. We offer access to spare parts, technical guidance, and consultation to help maintain optimal system performance. Our team remains available to address questions and provide assistance when needed. Maintaining strong client relationships ensures long-term operational success.

Our crushing systems are engineered for durability and strength. Many of our crusher types are designed to manage hard and abrasive materials common in mining operations. Equipment selection and proper configuration play an important role in performance. We help ensure that the chosen system aligns with the material characteristics of your project.

Yes, especially our gyratory and certain jaw crusher configurations, which are built for high-capacity applications. These systems are designed to handle substantial feed sizes and maintain consistent throughput. Large-scale mining operations benefit from equipment that balances capacity with durability. Our solutions are structured to meet those demands.

Absolutely. Although we are based in Vernon, BC, we supply equipment to clients across Canada and worldwide. Our crushing systems are designed for adaptability in various operating environments. International clients benefit from the same quality standards and support approach as our Canadian partners.

Partnering with OMRAISE allows us to offer advanced crushing and grinding technology backed by engineering expertise. This collaboration enhances our ability to provide systems that combine innovation, durability, and performance. Clients benefit from equipment that integrates modern design with proven industrial reliability. The partnership strengthens our overall commitment to delivering high-quality comminuting solutions.

Let’s Strengthen Your Crushing Performance

Your operation depends on equipment that performs consistently and efficiently. Whether you are upgrading an existing system or planning a new project, the right crushing solution can make a measurable difference in productivity and output quality.

Connect with our team in Vernon, BC to discuss your requirements and explore how our high-performance crushers can support your mining or aggregate operation. Together, we can build a system designed to move your materials forward with confidence.